Enterprise Name: Huizhou Yosingying Innovation Materials Co. Ltd..

Website:http://sigersonmorrison.cn

Contact: Mr. Zhuang 13609663446

Tel: 0752-6618779

Fax: 0752-6618783

Address: Second row on the South Side of Fengwu Village

Section, Qiaoqi, Shiwan Town, Boluo County, Huizhou City, Guangdong Province

How to distinguish between the good and bad of PVC seals

The characteristics of PVC seals:

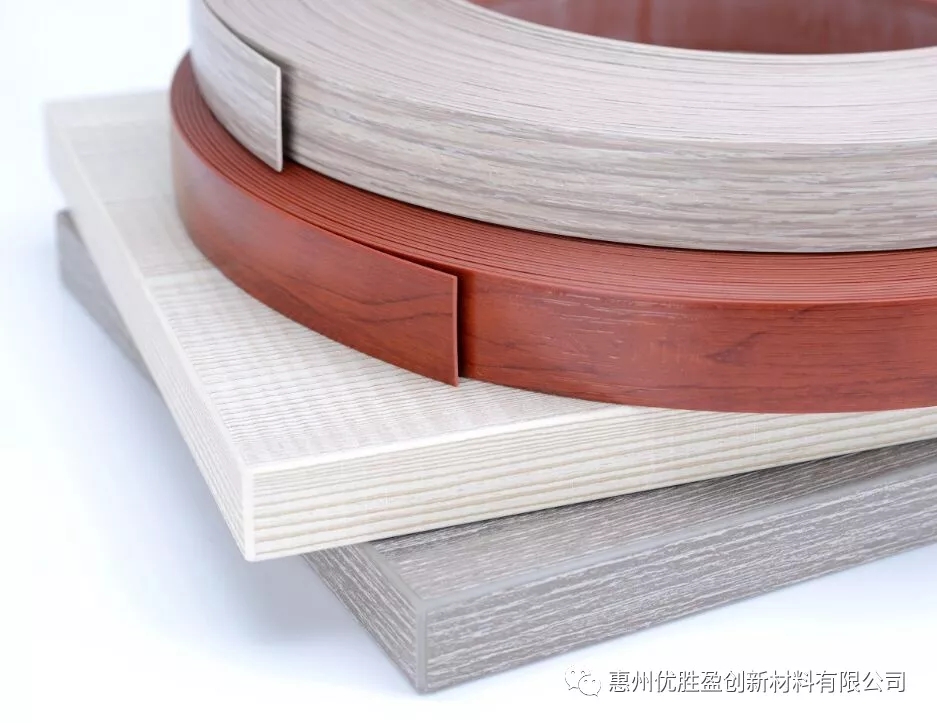

The PVC seal is a thermoplastic roll made by mixing and pressing with plasticizers, stabilizers, lubricants, dyes and other Auxiliaries, using polychloroethylene as the main raw material. Its surface has wood pattern, marble, cloth pattern and other patterns, the pattern at the same time the surface luster is soft, with the sense of reality and three-dimensional sense of wood; Has a certain degree of light and decorative, with a certain degree of heat resistance, chemical resistance, corrosion resistance, the surface has a certain hardness. The main function of the seal bar is to seal the section of the plate to protect the environment and the unfavorable factors(mainly water) in the use of the plate, and to prevent the formaldehyde volatilisation inside the plate, while achieving the decorative effect.

How to judge the quality of PVC seals:

1, look at the edge of the color and surface roughness, the good edge of the surface color is also very important, the color is similar to the custom product, gorgeous. If the surface is very rough and there are pull marks, then the quality must not be better. This is the surface quality of the sealing bar. There is not much relationship with the quality of the inner material of the seal bar, mainly the production technology of the seal bar factory and the production technology skills of the employees. The good edge bars are: the surface must be smooth, no bubbles or few bubbles, no lines or few lines, moderate gloss, not too bright or too dumb(unless there are special requirements).

2, look at the surface and bottom of the seal, whether the thick Pu is uniform, otherwise it will lead to the junction of the seal and the plate, the glue line is too eye-catching or the gap between the plate and the seal is too large to affect the overall United States. The details determine the success or failure, often a small detail, may lead to the overall effect of the awkward situation.

3, whether the edge of the trim is white, whether the surface of the bending seal is serious, whether the bottom color of the trim edge is close to the surface color of the plate. PVC seals are mainly made of PVC and calcium carbonate plus additives. If the content of calcium carbonate is too high, there will be phenomena such as sealing and bending and white, which will prove that the quality of such products is poor.

Whether the strength is still possible, there is no elasticity, strong high means good wear resistance, the corresponding quality is also better, too high strength also means that the processing difficulties increase. Low elasticity means low wear resistance and low aging resistance. According to the needs of actual production, it is generally necessary to repair the edges manually. It can be done properly, and the automatic sealing machine can be used as a hard point.

5, whether the back glue is uniform, in the use of whether easy to fall off.

6, smell the PVC seal has no taste, use the quality of raw materials produced by the product generally has a small taste, if the taste is too large, that means that the production of raw materials used poor quality.

7, look at the surface and bottom of the PVC seal, whether the thick Pu is uniform, otherwise it will lead to the junction of the seal and the plate, the glue line is too eye-catching or the gap between the plate and the seal is too big to affect the overall United States. The details determine the success or failure, often a small detail, may lead to the overall effect of the awkward situation.