Enterprise Name: Huizhou Yosingying Innovation Materials Co. Ltd..

Website:http://sigersonmorrison.cn

Contact: Mr. Zhuang 13609663446

Tel: 0752-6618779

Fax: 0752-6618783

Address: Second row on the South Side of Fengwu Village

Section, Qiaoqi, Shiwan Town, Boluo County, Huizhou City, Guangdong Province

Use and Attention of Enclosure Hot Melting Glue

1. Temperature at sealing

The heat melt of the sealing edge is affected by the temperature, so the temperature is a very important index in the sealing process. The temperature of hot melt glue, substrate temperature, material temperature and working environment(workshop of sealing machine) are very important sealing parameters. In the automatic sealing machine, due to the adhesive coating on the substrate, the base material with too low temperature will allow the hot melt adhesive to solidify in advance, resulting in the adhesive can be glued to the substrate, but it can not adhere to the sealing material. The temperature of the substrate is best kept above 20 °C. The working environment temperature of the sealing machine will affect the curing speed of the adhesive. Factory often in the season of low temperature will appear the problem of sealing edge, the reason is that the heat melt glue curing speed at low temperature speed, the effective time of bonding shortened. If the feed speed of the sealing machine can not be changed(in most cases), it is necessary to Preheat the plate and the sealing material to ensure the quality of the sealing edge.

2. Processing of sealing line

The adhesive line between the sealing plate and the sealing band will have an adverse effect on the appearance of the plate furniture. The amount of coating is too large, it will make the adhesive line obvious, and conversely, it will reduce the edge strength. For the non-continuous or uneven rubber line phenomenon, the reasons for this are manifold. The following factors should be considered comprehensively: the material opening accuracy of the plate, the edge of the plate must be maintained at an angle of 90 ° with its plane; Whether the pressure of the sealing machine roller is evenly distributed and suitable in size, the pressure direction should be 90 ° angle with the plate edge; Whether the coating roller is intact, whether the heat melt glue is uniform on it, whether the amount of coating is appropriate; Seal the edge of the plate as far as possible to keep in a cleaner, less dust, in the finishing process, to avoid dirty things and glue wire contact.

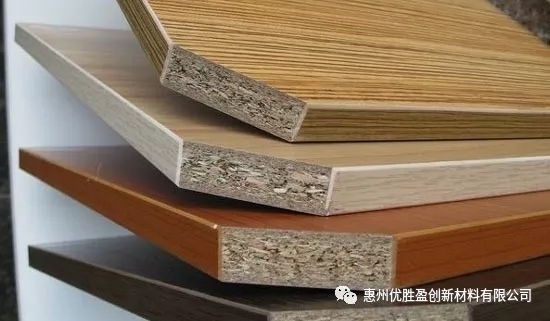

3. Requirements of hot melt adhesive for substrate and sealing materials

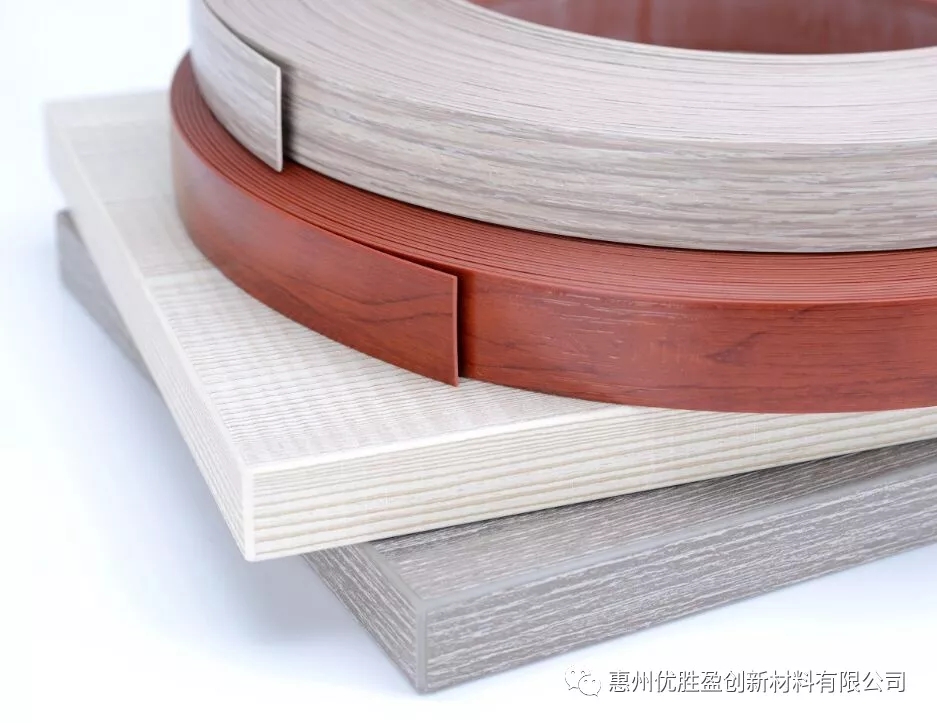

It is difficult to seal the edge of the base material rich in oil, and the oily material will reduce the affinity between the plate and the adhesive. When the time is long, the adhesion strength will be greatly reduced, causing the seal to fall off; In general, the temperature of the plate and sealing material must be kept above room temperature to ensure the quality of the sealing edge; The moisture content of sheet metal and wood skin can not exceed 12 %, and the water content is too high, which will make the thermal melt glue premature curing and wetting performance decline, thus reducing the adhesion strength; When the fireproof plate is used as a sealing material, because there is often a residual material on the back of the fireproof plate that is not conducive to adhesion, it is necessary to treat the back of the fireproof plate with a universal adhesive or a suitable solvent to obtain a good sealing effect. Some PVC side bands often cause difficulties in sealing because of poor back coating.

4. Matters to Note on the Use of Hot Melting Glue in the Maintenance of the Border Seal Machine

When the sealing machine is not working, the temperature of the plastic tank must be reduced to about 150 °C. On the one hand, it can avoid the carbonization phenomenon of the hot melt gum at the operating temperature for a long time, keep the plastic tank clean, and do not cause blockage of the rubber supply system. And reduce heating performance; On the other hand, when working again, it can quickly heat up the plastic tank to the operating temperature. In addition, more than 2/3 of the glue must be maintained in the plastic tank, otherwise it will produce black carbonates around the plastic tank; To regularly clean up the canister and coating roller, the excess carbon and residue around the canister will reduce the performance of the heating system and the rubber supply system; If you want to remove the residual glue in the glue tank, you can put a piece of T in the glue before the sealing machine stops working. When the glue is still in a melting state, the glue is completely cooled and then reheated. Since the glue on the bottom and around the plastic tank is first heated and melted, most of the remaining glue can be removed with T-shaped material. The residual gum is then cleaned with a 1:1 mixture of toluene and methylene chloride.