Enterprise Name: Huizhou Yosingying Innovation Materials Co. Ltd..

Website:http://sigersonmorrison.cn

Contact: Mr. Zhuang 13609663446

Tel: 0752-6618779

Fax: 0752-6618783

Address: Second row on the South Side of Fengwu Village

Section, Qiaoqi, Shiwan Town, Boluo County, Huizhou City, Guangdong Province

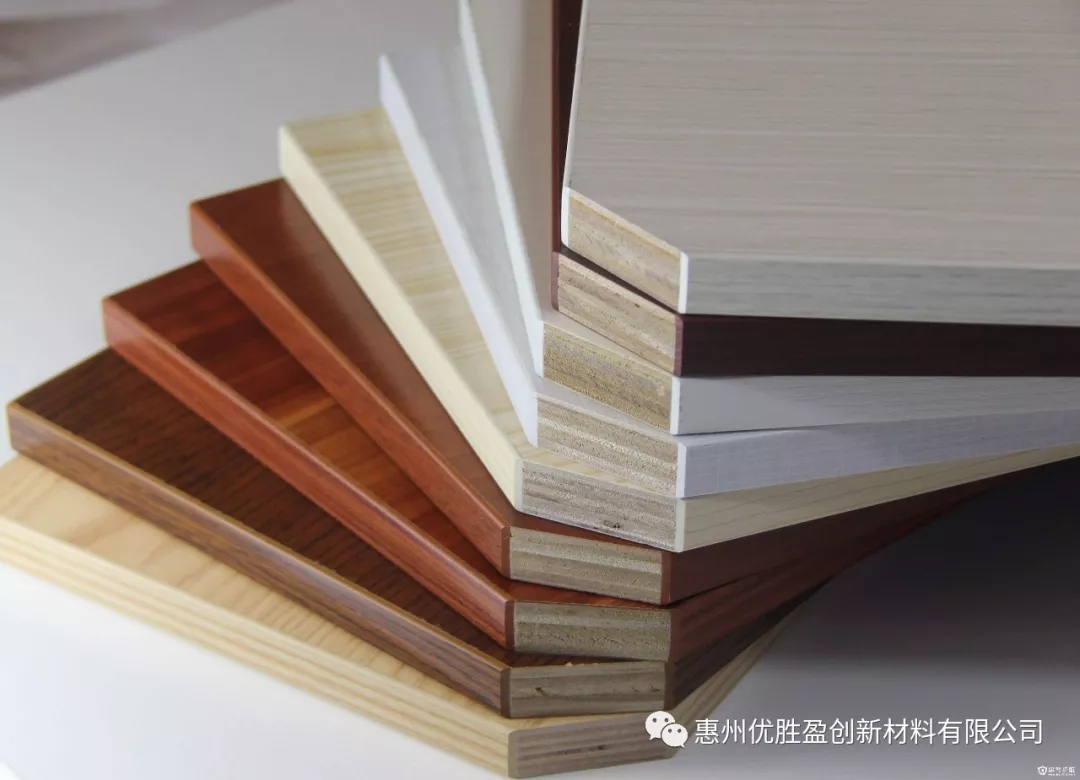

What if the cover of the board furniture falls off in large areas?

1, seal strip degumming mainly because the processor is too thin, especially PVC seal edge adhesive(treatment agent) coated too thin, resulting in a decrease in the affinity with hot melt glue.

2, technical issues. The temperature of the sealing machine does not reach the predetermined temperature, resulting in poor adhesion of the sealing strip and the hot melt adhesive. The temperature required by the high-temperature adhesive is generally 180 to 210 degrees, which can be adjusted according to the operating ambient temperature and the heating ability of the sealing machine. The temperature of the sealing machine.

3, the sealing machine glue is too thin, the production of the edge product itself is not qualified, which is also an important reason. The low-end hot melt gum on the market, due to its low strength, coupled with the fact that the gum is too thin, it is also common to cause degumming. In this case, some relief can be obtained by increasing the amount of coating. Or choose a hot melt with high strength and stable performance, such as the H-316, H-317 of Dongguan Yosemite Rubber Products Co., Ltd..

4, the uneven plate may also cause the furniture seal edge can not stick and fall off.

In addition, the shedding of the seal may also be caused by moisture, extreme cold or exposure. However, it is mainly due to the performance of the sealing strip and hot melt adhesive itself and the manufacturer's technical and technological reasons, and these reasons are actually caused by the merchant's interest trend. So how to prevent the phenomenon of edge strip falling off?

5. The use of high quality edge seals can reduce the phenomenon of edge falling. The general quality sealing strips have the following main characteristics: smooth surface, no foam, no pull pattern, moderate gloss, surface and back leveling, strong wear resistance, side color and surface color after trim edge sealing, And do not hair white, gloss, furniture product overall color coordination. Whether the surface and bottom surface of the seal is even or not, these will affect the combination of the seal and the plate. The rubber line is too eye-catching or the gap between the plate and the seal has a great impact on the overall beauty. That is the detail of success. Therefore, making cabinets or office furniture, etc., not only need to see the overall effect, the good or bad, beautiful or not, details on the overall impact of the product is very large.

6. Choosing a hot melt gum manufacturer with stable performance and good reputation, Yosemite, is a leading company in the home of a domestic hot melt rubber factory. It has the largest production capacity and the most professional technical team in the country. Solved many seemingly intractable problems for customers everywhere. Excellent product performance, bringing the entire market is unanimous praise.